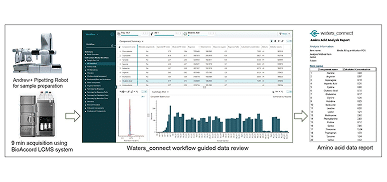

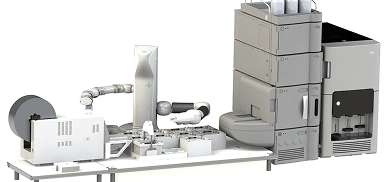

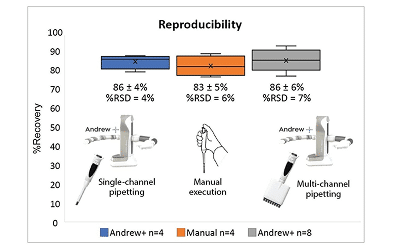

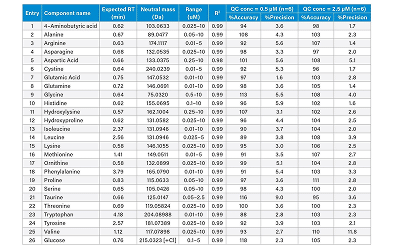

- Amino Acid Analysis

- Bioprocessing

- Cell and Gene Therapy

- DMPK: Automated Sample Preparation

- ELISA Assays

- Endotoxin Testing

- Forensic Toxicology

- Genomics

- Immunosuppressant Drug Monitoring

- Lipidomics

- Metabolomics

- Oligonucleotide Therapies

- Pesticide Analysis

- Protein Therapies

- Proteomics

- RNA Therapeutics

- RT-qPCR Testing

- Small Molecule Drugs

- Amino Acid Analysis

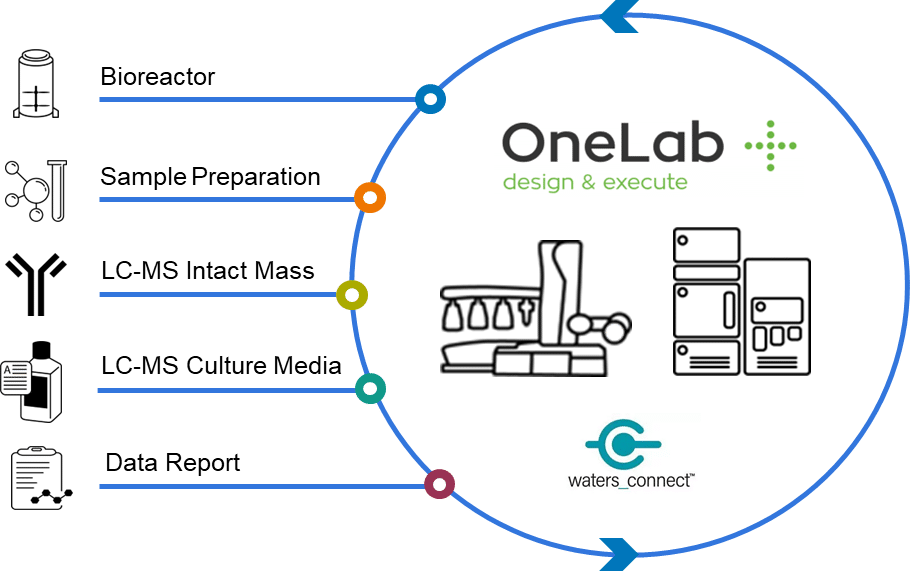

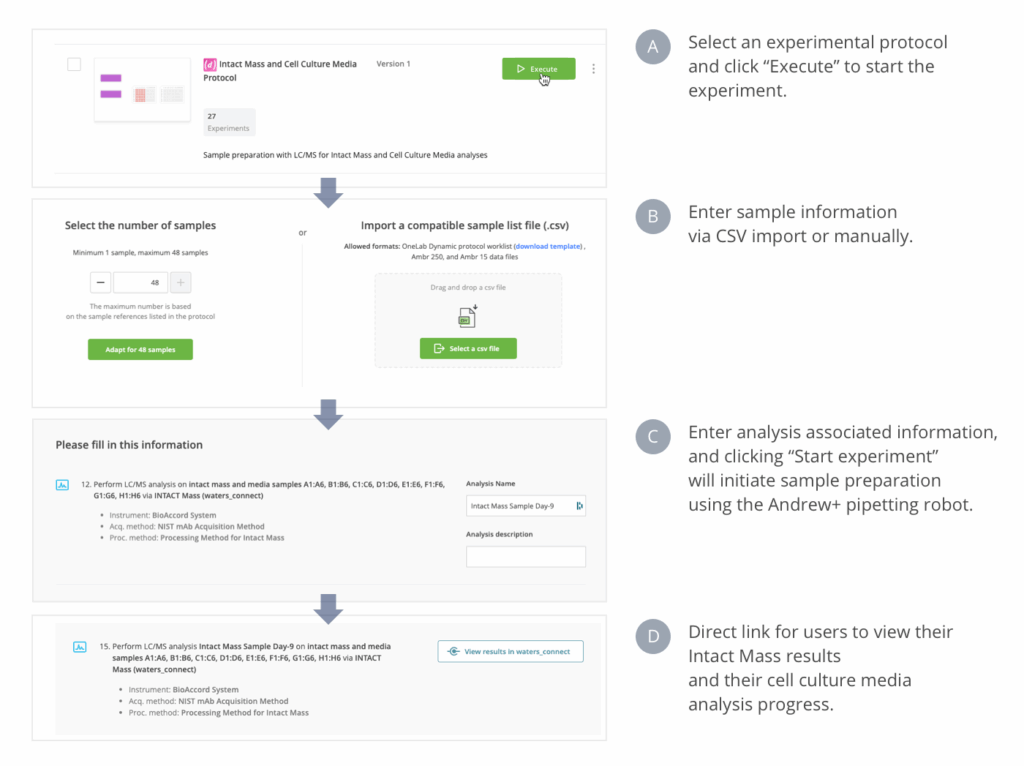

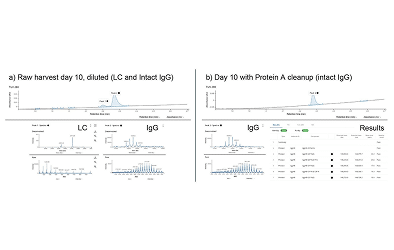

- Bioprocessing

- Cell and Gene Therapy

- DMPK: Automated Sample Preparation

- ELISA Assays

- Endotoxin Testing

- Forensic Toxicology

- Genomics

- Immunosuppressant Drug Monitoring

- Lipidomics

- Metabolomics

- Oligonucleotide Therapies

- Pesticide Analysis

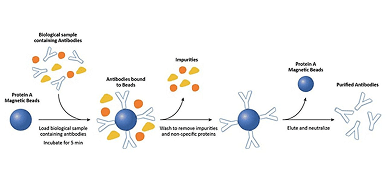

- Protein Therapies

- Proteomics

- RNA Therapeutics

- RT-qPCR Testing

- Small Molecule Drugs

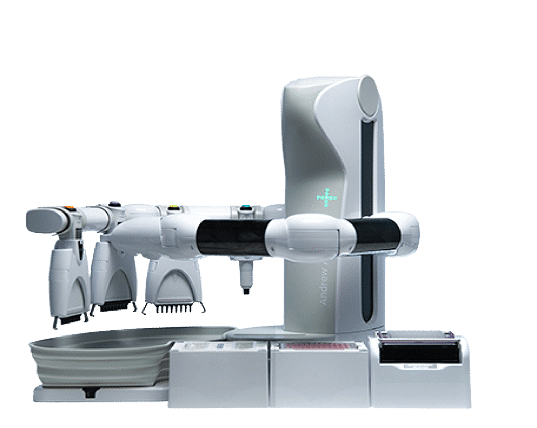

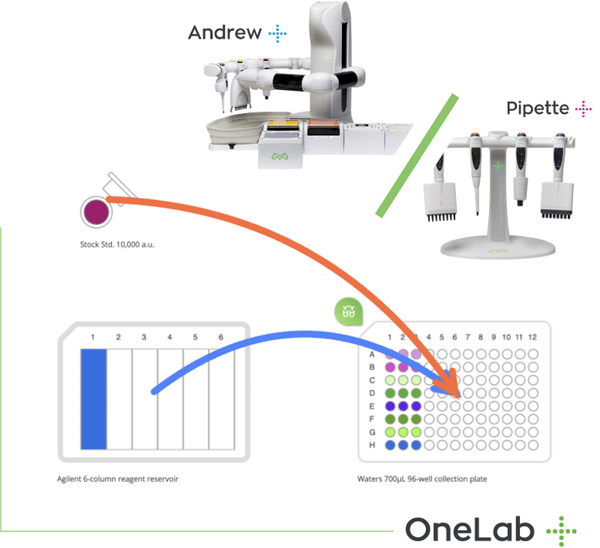

Master Serial Dilutions with Ease

From column-wise to row-wise preparation, streamline your dilution workflows with OneLab and Andrew+ for unmatched precision and reproducibility.

Looking for product support or a quote? We’re here to help. Nous contacter