Jackson Scheppers

Scientist, KBI Biopharma, Louisville, CO

The FDA’s approval of Orthoclone OKT3 (muromonab-CD3) in 1986 for the treatment of acute allograft rejection in organ transplant patients marked the beginning of a new era in immunotherapy. Since then, monoclonal antibodies have revolutionized the management of cancer, inflammatory diseases, and infectious diseases. However, the complexity of manufacturing these biologics has driven high costs, limiting patient access. The introduction of biosimilar monoclonal antibodies has significantly reduced the cost of biologic therapies, expanding global access for patients in need.

Headquartered in Hennigsdorf, Germany, northwest of Berlin, UGA Biopharma is an innovative biotechnology company dedicated to supporting the development of high-quality, safe biosimilars for patients worldwide. Under the leadership of CEO Dr. Eric Guenzi, UGA Biopharma’s team of international experts provides comprehensive support for biosimilar development, offering services that include cell line development, bioprocess optimization, purification, and analytical characterization. Their ready-to-use (R2U) CHO-based cell lines and CHO-based cell culture media are widely used across numerous customer projects in biologics and biosimilars development.

To ensure the safety and efficacy of its biosimilar development, UGA Biopharma has established specialized analytical laboratories equipped with advanced LC-MS instrumentation. Analytical Chemists routinely perform peptide mapping and amino acid analysis using chromatographic techniques to monitor protein integrity and detect subtle changes that may influence the quality of biosimilar candidates. In addition, comprehensive glycan profiling is performed regularly to ensure the quality and integrity of biosimilar mAbs.

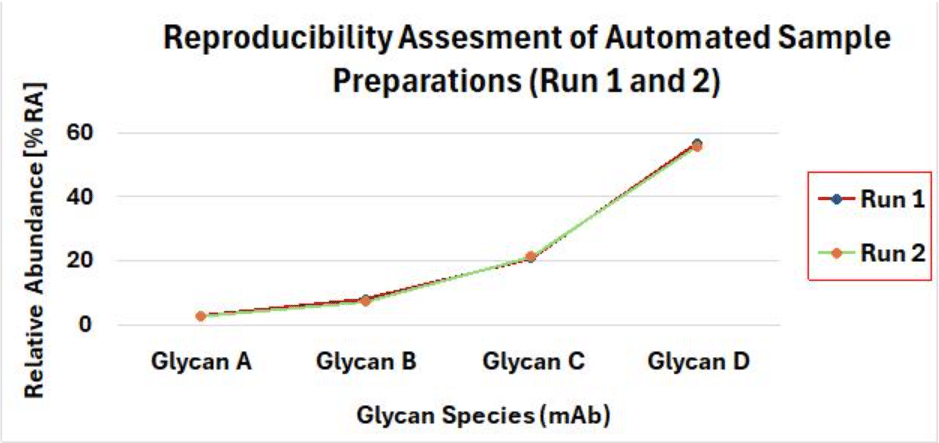

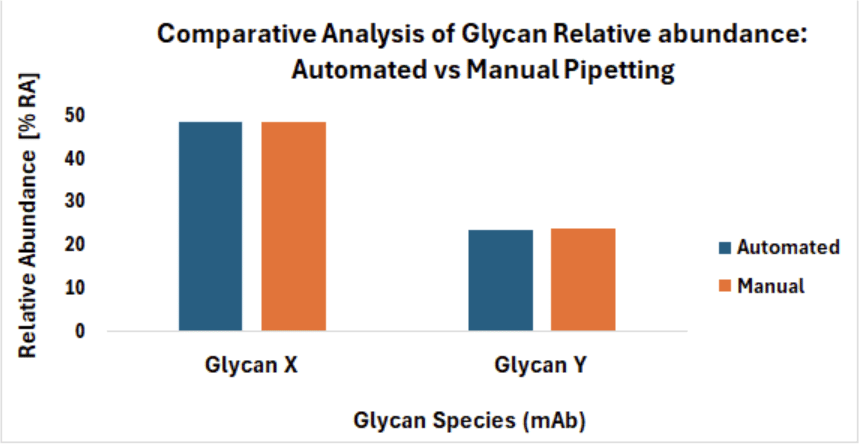

The glycan profile of a monoclonal antibody (mAb) is a critical quality attribute (CQA) that significantly impacts its target-binding efficacy. Even minor variations in glycan composition can lead to aggregation, alter pharmacokinetic behavior, or elicit immunogenic responses. To simplify and standardize sample preparation for N-glycan analysis of biosimilar mAbs, scientists at UGA Biopharma adopted the GlycoWorks™ Kit from Waters.

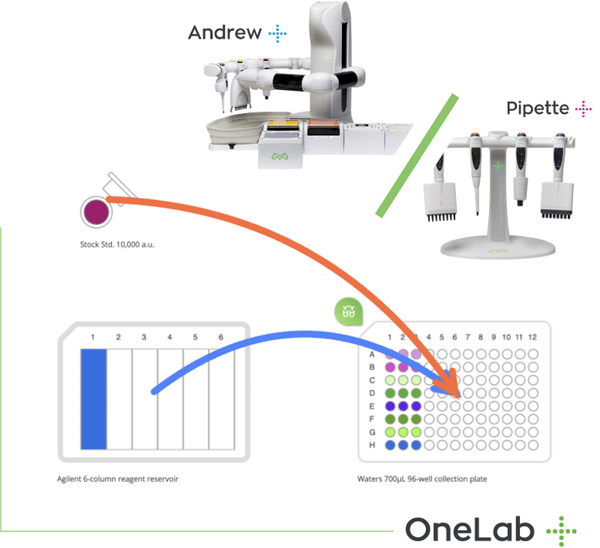

“Imagine an analyst preparing 48 samples for glycosylation profiling, involving nearly 700 pipetting and mixing steps performed manually with a single-channel mechanical pipette. The process demands unwavering attention and patience as each liquid transfer must be as accurate as possible. Even with skilled hands, subtle variations can slip in, compromising the reproducibility required for biosimilar characterization,” replied Sazzad Ul Karim, a member of the Analytical Development Team at UGA Biopharma, when asked about some of the challenges he has faced with glycan profiling. Sazzad was enthusiastic to learn during a Lunch & Learn session that the entire GlycoWorks Sample Preparation Workflow can be fully automated using the Waters Andrew+ Robot.

“Working with Waters has been seamless and highly productive. When our team requested the integration of specific labware with OneLab™ Software, the implementation was completed promptly and without complications. The Waters AI Advisor demonstrated exceptional accuracy, far surpassing typical chatbot performance as it resolved technical queries instantly and reduced the need for additional human intervention. Equally impactful, the Dynamic Protocol feature introduced a new level of flexibility, automatically adjusting to variations in sample number, volume, and layout,” commented Sazzad when asked to evaluate his experience with the Andrew+ Robot.

“We are very excited about exploring other applications of the Andrew+ Robot such as sample preparation for peptide mapping and amino acid analysis,” said Ms. Wiebke Hannemann, Team Leader of Analytics and DSP. “Both Sazzad and the Andrew+ Robot are very strong when it comes to preparing mAb samples for glycan analysis. Thanks to the Andrew+ Robot in our lab at UGA Biopharma, Sazzad can focus on solving much more complex problems and leave glycan profiling sample preparation for the Andrew+ Robot,” added Wiebke.

Waters, Andrew+, GlycoWorks and OneLab are trademarks of Waters Technologies Corporation.