Many R&D organizations have team members working remotely: Cloud-native design, execution and sharing of protocols are essential

One of the ironies of the situation we had find ourselves in today is that many of us are having to work from home in our ‘home offices’ whilst trying to accelerate the development of urgently required diagnostics and therapeutics. Under the most optimal conditions, such R&D activity takes vast resources and time but now that those same teams have had to operate in disparate locations, many away from the familiar laboratory environment, it all becomes even more challenging!

As Vivian Greene once said, “Life isn’t about waiting for the storm to pass, it’s about learning how to dance in the rain.”

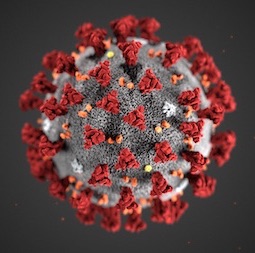

This couldn’t be more true as we strive to find new, innovative ways to drive forward research fronts at a faster rate than could have been imagined up until only recently. This is true whether the goal is to improve the speed and reliability of an RT-PCR test for detection of the SARS-CoV2 virus, reduce the number of false positives demonstrated by serological tests used to identify persons who have suffered the resulting COVID-19 infectious disease. Once the virus mutates into a different form, a different immune response will be required, further complicating the race to develop new vaccines and treatments aimed at future prevention and disease management.

The COVID-19 Pandemic has permanently changed the way we work

These requirements demand automation to scale up sample processing and assay development for a range of different assay methods, whilst assuring superior repeatability and improved productivity. We know that, in part because over the last few decades this has been the benefit brought by automation, but also because this is one of the critical rate limiting steps in successful commercialization.

The challenge is that automation solutions often involve in-situ laboratory-based programming knowledge in order to adjust experiment protocols, consistent with the rapidly evolving understanding of both the virus and resulting disease. This is, after all, the nature of the scientific method!

It also requires highly flexible automation, capable of running a serial dilution in the morning, and perhaps an ELISA sample prep in the afternoon, or a DNA/RNA extraction. Most important, it demands a solution that can be easily set-up and managed remotely.

Cloud-native solutions enable teams to conduct critical lab work remotely

It was very much for these sorts of situation that Andrew Alliance set up its ‘+’ suite of products, managed within the ever evolving connected lab ecosystem of OneLab. With OneLab, a biologist, with zero experience of programming in any computer language (never mind C++ or Python) can easily set up their protocol, either by using one from Andrew Alliance’s OneLab Online Protocol Library, or by designing it themselves, in their home office, on their laptop or table; the software being, of course, cloud-native, and freely accessible. In this case, ‘simple’ means dragging and dropping the required labware, selecting and setting pipette dispense/aspirate volumes, defining any required actions on special ‘connected devices’ that shake plates (Shaker+), rapidly heat/cool plates (Peltier+), separate beads (Magnet+) or do micro-elution for solid phase extraction (SPE) prior to LC-MS (Vacuum+).

Flexible liquid handling automation supports accelerated method development

Not only is this easy to set up in your home office, but it is also easy to execute on a liquid handling robot hosted in a different location, such as within a biosafety hood in a laboratory. Direct communication between cloud-native OneLab and the Andrew+ liquid handling robot enables such remote execution, and since that communication is ‘two-way’, each executed step is recorded enabling not only full traceability but also providing a means of troubleshooting problems.

Tools that enable cloud-based remote operation, tracking and sharing of critical protocols have become an essential requirement

Remote operation from a home office is one part of this, flexibility of the liquid handling automation another.. but a third aspect is ease of ‘method transfer’. At some point, experimental work needs to be successfully replicated by another lab, either within, or external to, an organization, perhaps as part of a ‘ring trial’. OneLab’s cloud-native environment facilitates such method transfer, obviating yet another source of error in the scientific community, misinterpretation of protocols disseminated via peer reviewed journals. Such errors can delay research by many months.

Mammoth Biosciences: A use case for remote working

One company, Mammoth Biosciences, a company based in South San Francisco, which uses its novel CRISPR Gene Editing technology to develop new molecular diagnostics as well as advance the discovery of CRISPR associated (Cas) proteins, some of which play a vital role in the immunological defence of certain bacteria against DNA viruses and plasmids.

Following lockdown, they ran into the challenge of how to advance the development of a novel COVID-19 diagnostic despite having a number of key research staff having to work from home.

Mammoth uses the award-winning Andrew+ liquid handling robot, together with OneLab cloud-native software with one researcher designing and executing protocols in her home office, while a lab technician ensures that the robot’s workspace is set up with the required labware and consumables. Protocol execution is monitored live using Zoom.

This has ensured that planned experimental work has been able to proceed unimpeded!

James Broughton, Research Leader at Mammoth Biosciences sitting in front of an Andrew+ Liquid Handling Robot, explaining the importance of being able to remotely operate the robot using OneLab cloud-native software

As we look to the future, it is clear that there is much to learn from the current COVID-19 pandemic and ensuing crisis. Part is how to ensure that we have R&D infrastructure ready and able to conduct R&D in a distributed environment, and part is the way in which we adapt to what will be more permanent changes in the way we work. On example of the latter is the way that Andrew Alliance has adapted its customer experience to such an environment:

-

Product demonstrations are given online by a team who have built up expertise in hosting ‘e-demos’ over the last 5 years. This increases productivity whilst reducing CO2 footprint as it obviates the need for travel

-

Deminars provide an open forum for educating a broader community of researchers to the merits of Andrew Alliance products, replacing an experience typically experienced in the ‘trade show’. Trade shows will ‘return’ but it is highly unlikely that this will be in the same form as before. It is widely believed that a more hybrid format will be adopted, fusing an online experience with a face-to-face event.

-

Technical support as Andrew Alliance uses INTERCOM which enables customers immediate access to a support representative via the website. Response times average at 80 seconds and customer experience is consistently ‘very high’.

Andrew Alliance is well known for its agile, customer-centric approach to every aspect of its product development. It comes as perhaps no great surprise that its ability to respond quickly to COVID-19 and the urgent requirements of many labs around the world, has indeed been a case of ‘dancing in the rain’! Proud to be part of the ‘Waters Family’, this approach is now being amplified and the ‘connected lab of the future’ coming ever closer!

Learn more at www.andrewalliance.com