Indeed, it is one of the workhorses of the lab and a core skill for many scientists.

For example, in drug discovery, IC50 assays, commonly used to evaluate drug efficacy, and assay development procedures as well as standard-curve generation involve the serial dilution of compounds, proteins, or detection agents. These processes can be streamlined by utilizing automated liquid handling equipment with serial dilution capabilities, addressing two common workflow challenges: error propagation across the columns or rows of a microtiter plate due to transfer inaccuracies that lead to less accurate and less precise dispensing; and the risk of error in the calculation of serial dilutions themselves.

This is all well and good but any automation solutions on the market have been developed for high throughput liquid handling, are specific to a limited range of applications, and are priced beyond the budget of many research laboratories who cannot justify investment in automation for lower throughput liquid handling despite unquestionable improvements in reproducibility of the liquid handling steps in their workflow. This is especially the case if the ‘solution’ cannot be readily adapted to different workflows unless the researcher is well versed in Python or C++, as well as being willing to invest the time in reprogramming their lab automation or hire a programmer, and that is assuming that it can even be reprogrammed, i.e. is an ‘open’ vs ‘closed’ lab automation solution. Moreover, unlike many ‘ideal’ lab bench set-ups in trade shows, reality is usually very different, with the modern lab being increasingly ‘rented’, space constrained and it has become more important than ever that an automation solution be readily adaptable to different researcher workflows rather than the other way around, most especially in the earlier stages of research. Fitting a rectangular ‘box’ into a space under a laminar flow hood is rather like trying to fit a ‘square peg into a round hole’.

Do you feel in control of your lab automation.. or is it controlling you.. or is it parked in the corner of the lab doing nothing at all?

The answer to this question likely explains why many laboratories still rely on manual operations to perform tasks, especially when it comes to liquid handling. Fully automated workflows have been achieved in the field of clinical diagnostics, but the same can’t be said for research, due to the flexibility and continuous workflow changes required.

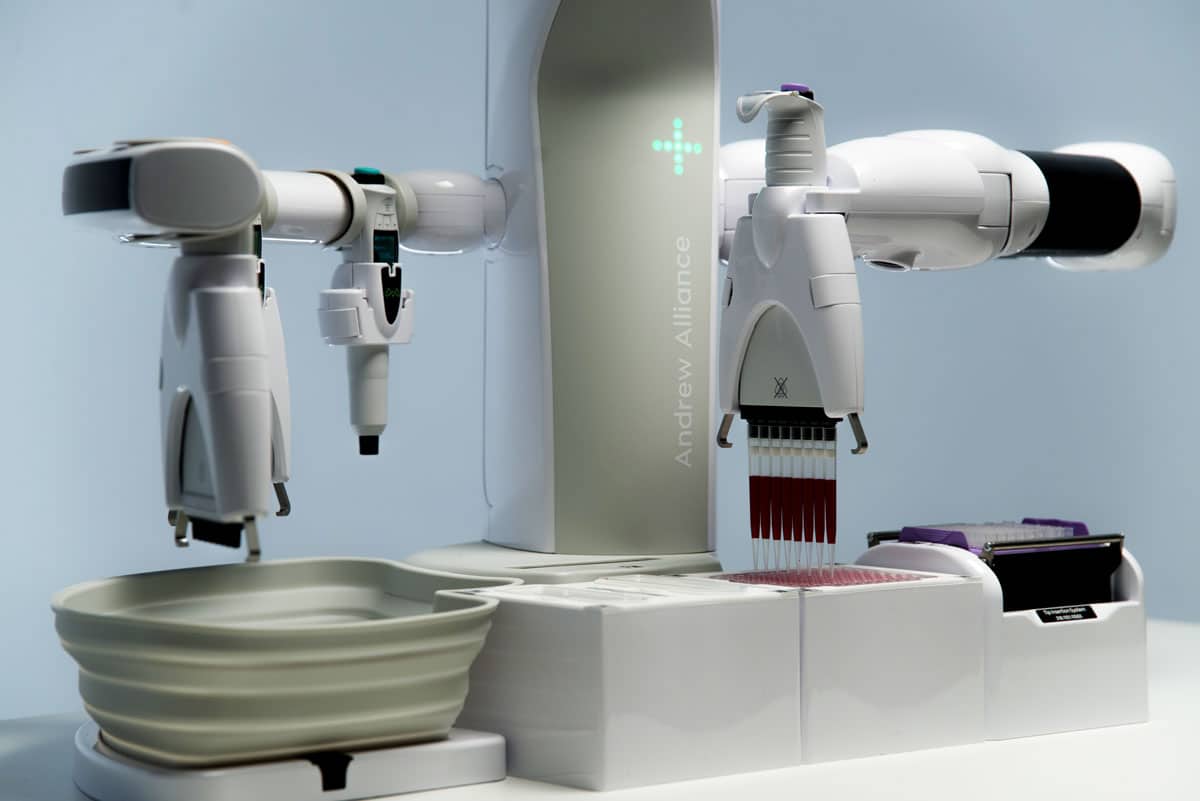

Andrew Alliance has addressed this need in its recent launch of the award-winning Andrew+ robot that is capable not only of automating liquid handling but the manipulation of labware crucial to sample management inherent to many research workflows.

The robot is managed by its state-of-the art browser-based intuitive lab software called OneLab which allows the researcher to not only retain control of their workflow but readily adapt the pipetting robot to a wide range of other workflows using Andrew Alliance Domino accessories, thus making optimal use of space, resources and funding. OneLab requires zero programming know-how. Pick up your tablet or laptop, drag and drop the labware you require, volumes to be aspirated/dispensed, calculate your serial dilution in a way that is both highly visual, easily shared with other researchers, and even fun.. and you are ready to go!

This is just part of the story.. two-way communication with Bluetooth pipettes means that each step in the execution of your protocol is recorded along with the calibration data of the pipette itself. This ensures full traceability as well as a high degree of quality control, especially important if you want to automate costly and complex liquid handling steps associated with qPCR or NGS. in a simple qPCR experiment, typical pipetting errors with a standard, routinely calibrated pipette, can result in DNA copy numbers varying by as much as 3%. Imagine the impact of that on the results of an important translation biology experiment, or in a regulated diagnostic laboratory!

The Andrew+ itself is based upon the multi-award winning, highly successful, Andrew Pipetting Robot, launched in 2013 and used in many laboratories around the world.

It offers fully automated pipetting, as well as more complex manipulations, using a wide range of accessories and Andrew Alliance electronic pipettes. Significantly, compared to its predecessor, it hosts 8 and 12 channel pipettes enabling much larger volumes to be dispensed far more quickly. This is a significant advantage, for example in qPCR and NGS workflows. It is a complete ‘redesign’ with the ‘+’ referring to the fact that it is a fully ‘connected’ device, able to communicate with both OneLab, by ethernet or Wi-Fi, from which is receives step by step guidance of each step of a given protocol; and with the electronic pipettes themselves, by Bluetooth. This communication is two-way, with instructions being passed from OneLab to Andrew+, which ensures the remote programming of the pipettes, and back from the pipettes to OneLab, meaning that each step if being fully recorded.

The electronic pipettes comprise a full range of single and multichannel versions, dispensing volumes ranging from 0.2 μl to 10 mL. They are manufactured by Sartorius in Kajaani, Finland, and based on its market leading high performance Picus design. These are branded Andrew Alliance as they have been co-developed with Andrew Alliance so that they can work with OneLab. The pipettes are automatically paired with OneLab via special adapter on the rack to which they are mounted, and this process does not require any user intervention at all.

Andrew+ has a highly flexible workspace. It is modular thanks to the use of Dominos. A simple experiment requires only 2 Dominos whereas Andrew+ could manage up to 11 Dominos for more complex experiments. The system has been designed to fit the majority of laboratory hoods. Andrew+ with 2 full rows of Dominos occupies a depth of ~60cm/24”, which would be viable for even the most challenging of hoods.

Each year at the Society of Laboratory Automation and Screening International Conference and Exhibition, the New Product Award is given to up to three companies showcasing new products that are commercially available within 90 days pre- and post-conference. Products are evaluated by a judging panel onsite at the companies’ booths. Winning products are granted use of the New Product Award designation for a year. Andrew+ won the New Product Award in February 2019.